Solar Power

SOLAR THERMAL POWER PLANT -

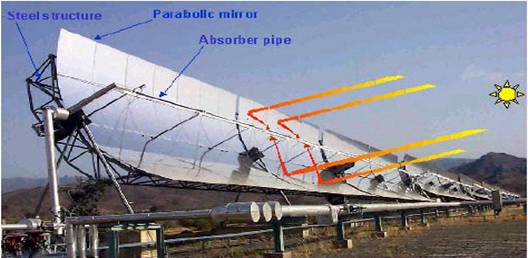

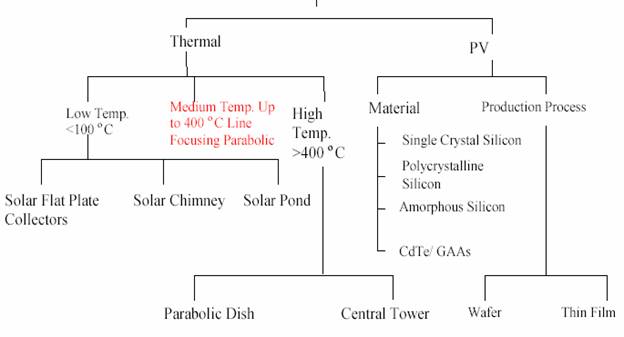

Solar thermal power plants are basically power plants, which generate electricity from high-temperature heat. The difference between them and conventional power plants: not gas, coal, or oil, but the sun provides the energy that drives the turbines. In Solar thermal power systems mirrors are used for focusing the sun onto receivers by point or line focusing; thereby increasing the temperature of circulating fluid at the receivers. For eg: In Parabolic (trough) system, mirrors can focus the sun at 30 to 60 times its normal intensity on a receiver pipe located along the focal line of the trough. Synthetic oil captures this heat as it circulates through the pipe, reaching temperatures as high as 400ºC. The hot oil is pumped through a heat exchanger on the power production side of the plant to produce steam. Electricity is produced in a conventional steam turbine/generator The power cycle is completed with the condensing of the steam through a cooling tower and then pumping it back through the heat exchanger connected to the solar energy collection field.

Solar towers consisting of a central receiver tower, which is surrounded by a mirror field that concentrates the irradiation (Point focusing) on the tip of the tower. In the receiver a heat transfer medium is used to transfer the energy to a heat exchanger in order to produce steam. With the Dish-Stirling system, parabolic dishes capture the solar radiation and transfer it to Stirling motors.

TECHNOLOGIES -

Technology components -

• Solar field – Technology type,

• Temperature

• Receiver

• Storage

• Power plant systems – Working fluid –

• Power plant cycle

• Hybrid/ Solar only

• Rating

SOLAR PHOTOVOLTAIC POWER PLANT -

|

Basic Principle: The sun illuminates the solar cells in the PV Array, which convert the energy in the sunlight into electricity. The electricity goes into an inverter and into the power lines to your homes.Semiconductor materials such as silicon are used in these photovoltaic solar cells. In the cells incoming photons separate positive and negative charge carriers. This produces an electrical voltage and the electrical current can drive a load. Since solar cells are modular, they can be assembled in units of any size. An inverter converts DC voltage to AC and feeds the solar power into the grid. Groups of solar cells can be packaged into modules, panels and arrays to provide useful output voltages and currents to provide a specific power output |

Components -

Solar Arrays, Inverter, Transformer

Technologies available -

- Conventional Silicon based

- Monocrystalline technology

- Polycrystalline technology

- Thin film technology

- Concentrating PV (CPV): latest emerging

PV Modules:

|

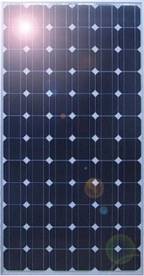

To make modules, PV manufacturers use crystalline silicon wafers or advanced thin film technologies. In the former, single crystal silicon (single-Si), polycrystalline silicon (poly-Si) or ribbon silicon (ribbon-Si) wafers are made into solar cells in production lines utilising processes and machinery typical of the silicon semiconductor industry Solar cell manufacturers then assemble the cells into modules or sell them to module manufacturers for assembly. Because the first important applications of PV involved battery charging, most modules in the market are designed to deliver direct current (DC) at slightly over 12 Volts (V). A typical crystalline silicon module consists of a series circuit of 36 cells, encapsulated in a glass and plastic package for protection from the environment. This package is framed and provided with an electrical connection enclosure, or junction box. Typical conversion (solar energy to electrical energy) efficiencies for common crystalline silicon modules are in the 11 to 15% range.

|

|

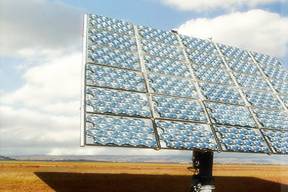

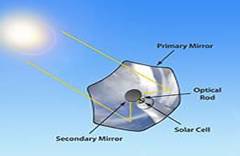

CPV -

|

|

|

Latest Emerging PV technology -Uses Space quality solar cell with high efficiency and optical lenses for concentration ( High Concentration Ratios: 200-1000). |